As the electric vehicle (EV) market continues its meteoric rise, with a projected compound annual growth rate (CAGR) of 22.6% from 2021 to 2028, the demand for high-quality EV cables has never been greater. Leading factories in China are spearheading innovations in EV cable production, ensuring that they meet international standards and cater to diverse global markets. According to a recent report by Allied Market Research, the global EV cable market reached $1.57 billion in 2020 and is expected to exceed $6 billion by 2027. This surge underscores the critical role that manufacturers play in delivering reliable and efficient EV charging solutions. By harnessing cutting-edge technology and optimizing production processes, China's factories are not only enhancing their competitiveness but also contributing significantly to the sustainability goals across the globe, making them indispensable players in the EV ecosystem.

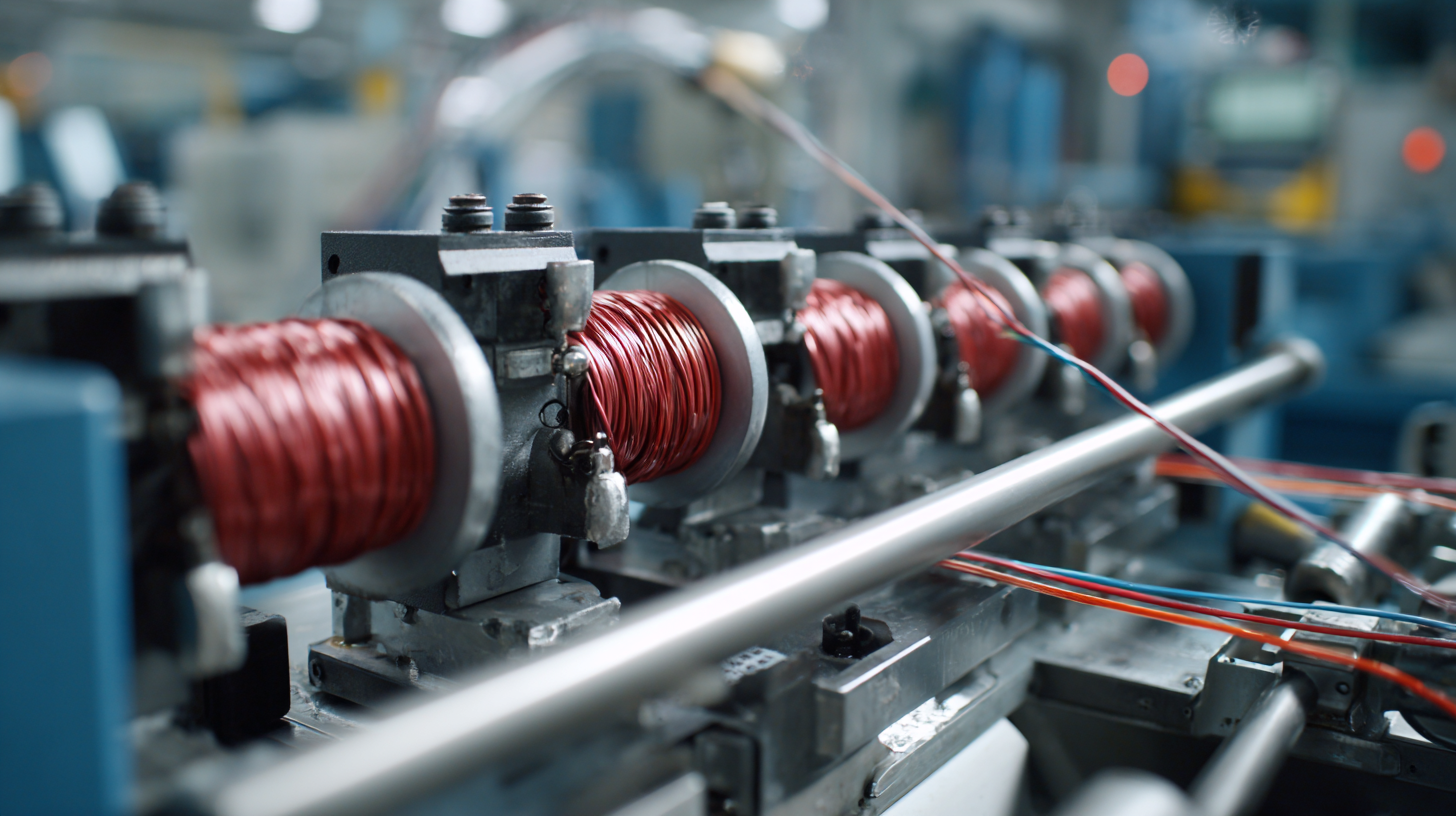

In the rapidly evolving electric vehicle (EV) industry, the choice of cable type is critical for optimizing production efficiency and performance. The common types of EV cables include high-voltage (HV) cables and low-voltage (LV) cables, each with its unique advantages and disadvantages. According to a report by MarketsandMarkets, the global demand for EV cables is projected to grow at a CAGR of 17.8% from 2022 to 2027, largely driven by increases in EV adoption and charging infrastructure development. HV cables, while essential for efficient power transmission in higher-range vehicles, can be more complex to manufacture. This complexity often results in higher production costs and longer lead times.

On the other hand, LV cables, which are primarily used for internal vehicle wiring and charging systems, typically have lower production costs and are easier to handle. However, they may not support the high power and efficiency demands associated with newer EV models. A comparative study from the International Energy Agency reveals that while HV cables are more efficient for long-distance travel, the use of LV cables remains essential for urban EV applications, where charging stations are more frequent and range demands are lower. Striking the right balance between these types can significantly impact the overall quality and competitiveness of EV offerings in the global market.

The landscape of electric vehicle (EV) cable production is rapidly evolving, driven by advancements in technology and increasing global demand. As manufacturers in China strive for excellence, the differentiation between standard and high-performance EV cables becomes essential. High-performance cables typically feature enhanced conductivity and insulation, which are critical for supporting the needs of rapid charging and high power delivery. Industry reports estimate that the cable connectors and adapters market will reach a valuation of USD 97.3 billion by 2025, with a compound annual growth rate (CAGR) of 7.9%. This growth reflects the burgeoning demand for efficient charging solutions that high-performance cables provide.

When selecting cables for EV applications, consider these tips: First, ensure the chosen cable meets specific power requirements and withstands environmental factors such as temperature and moisture. Second, look for cables with advanced protective features to prevent overheating and electrical faults during high-power operations. Finally, don’t overlook the importance of regulatory compliance, as adherence to international standards can significantly impact interoperability and safety in charging infrastructures.

With the push toward advanced automotive technologies and higher efficiency standards, the role of EV cables is more critical than ever. As the industry shifts toward electrification and the integration of autonomous systems, investing in high-performance cables could prove crucial for manufacturers aiming to thrive in this competitive market.

As the electric vehicle (EV) market continues to expand rapidly, the demand for high-quality EV cables has surged in 2023. This year, manufacturers are observing a significant trend towards lightweight and high-conductivity materials that enhance energy efficiency and reduce overall vehicle weight. The push for sustainable and eco-friendly alternatives is also influencing preferences, with many consumers and manufacturers looking for recyclable or biodegradable cable options. With multiple EV brands vying for customer loyalty, the need for superior cable performance has never been more critical.

Moreover, advancements in technology have led to innovations in cable design, reflecting market needs for faster charging and increased safety. Companies are focusing on producing cables that can withstand higher voltages and temperatures, responding to the demands of next-generation EV models. This shift is particularly noteworthy in China, where leading factories are optimizing their production processes to meet global standards while catering to local preferences. The interplay between market demand and production capabilities is crucial for manufacturers aiming to secure their place in the competitive EV landscape.

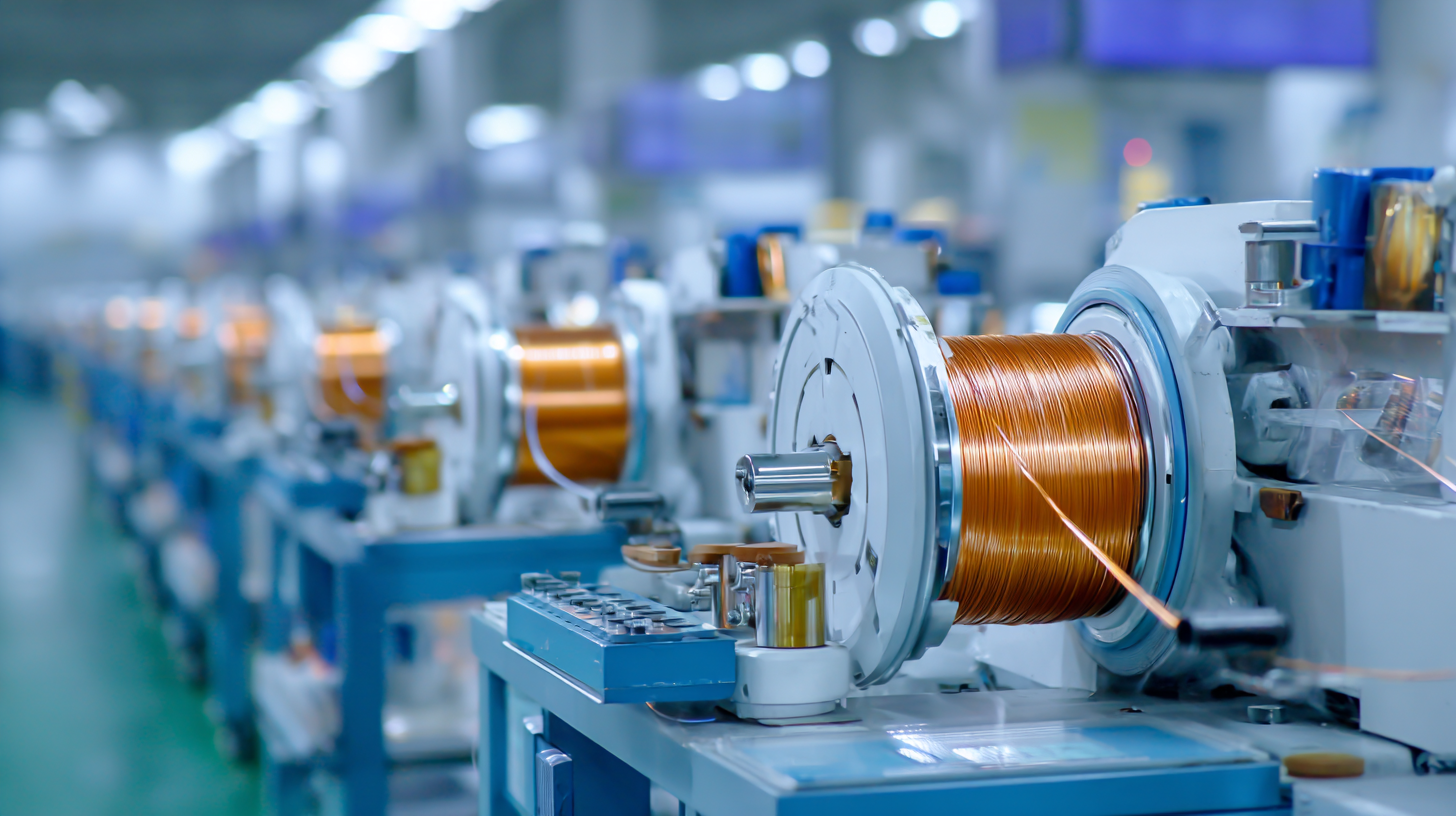

The selection of materials for electric vehicle (EV) cables is critical in determining their efficiency and longevity. As the demand for EVs continues to surge, manufacturers are focusing on high-quality materials that can withstand varying environmental conditions while ensuring optimal performance. Copper remains the preferred choice due to its excellent conductivity; however, innovations in alternative materials like aluminum are gaining traction. These advancements not only help in reducing the overall weight of the cables but also in enhancing energy efficiency, crucial for maximizing the range of electric vehicles.

Moreover, insulation materials play a pivotal role in the durability of EV cables. High-performance options such as cross-linked polyethylene (XLPE) and thermoplastic elastomers ensure that cables can resist heat, moisture, and abrasion, thereby extending their operational lifespan. Additionally, the use of protective coatings can significantly reduce the risk of wear and tear, ensuring that cables maintain their integrity even in harsh conditions. As China's leading factories innovate and refine their production processes, the emphasis on material selection will undoubtedly drive the evolution of EV cable technology, leading to safer and more efficient electric vehicles for global markets.

As the electric vehicle (EV) market continues to surge, China stands at the forefront of cable manufacturing, driving future innovations essential for global distribution. According to a recent report by Allied Market Research, the global EV cable market is expected to reach $1.86 billion by 2027, growing at a CAGR of 25.1% from 2020. This robust growth is fueled by the increasing demand for electric vehicles and stringent government regulations promoting clean energy solutions.

Chinese manufacturers are leveraging advanced technologies such as automated production processes and artificial intelligence to enhance operational efficiency and product quality. Reports from Statista indicate that China’s EV production capacity has increased dramatically, with nearly 3.3 million units produced in 2021 alone. This development has prompted factories to innovate and develop high-performance cables that can withstand extreme conditions, enhancing safety and reliability for users around the world. Innovations such as lightweight materials and integrated smart features are becoming pivotal in ensuring that EV cables meet the diverse needs of modern vehicles, thereby solidifying China’s role as a leader in the global EV cable market.